ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreGet the full ReeForm brochure with specs, configurations, and performance benefits—download now.

Features & Benefits

- Stainless steel construction

- Remote access

- Production reporting

- SMC pneumatics

- IP 65 sanitation rating

- Vacuum skin pack capable (VSP)

- Modified Atmosphere Packaging (MAP)

- Complete range of equipment to best fit your application

Form fill seal machines produce a variety of package types for the customization of your products.

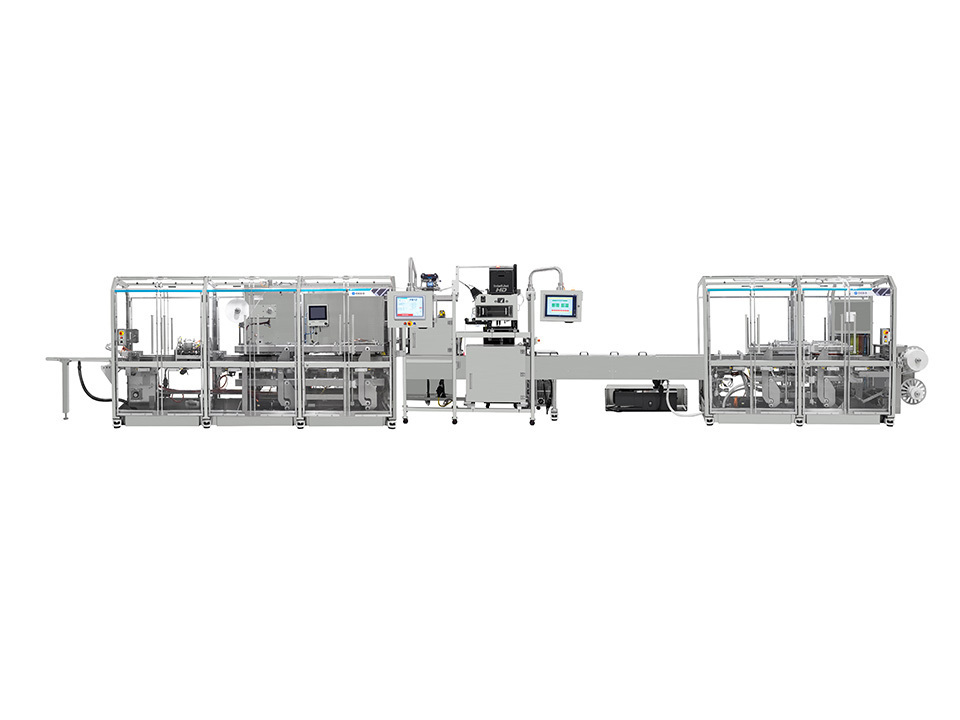

The ReeForm Series are thermoforming packaging machines that offer a wide range of machine options to meet customers' individual requirements. Series include machines from entry-level, flexible film only, and compact models up to high performance customizable machines capable of forming flexible and rigid films, a range of film widths, forming depths and cut-off lengths.

Options

- Remote monitoring and diagnostics available

- Integration and supply of thermal transfer printers, printers, labelers, etc.

- Integration of product feeder/loaders, fillers, etc.

- Pre heat station

- Package development and prototyping services

- Other control packages available

Package Types

- Flexible Packaging

- Saddlepack packaging

- Foil-Foil Packaging

- Semi-Rigid Packaging

- Rigid Packaging

- Ambient Packaging

- Vacuum Packaging

- Modified Atmosphere Packaging (MAP)

- Vacuum Skin Pack (VSP)

- Re-closable Packaging

- Microwaveable Packaging

- Oven safe Packaging

- Sealing Solutions

- Tray Pre-cut

- 90 degree cut

- Euro Hole

- Easy Open

- Cur with Round Corner

- Zig Zag Cut