ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreForm Fill Seal Packaging Equipment

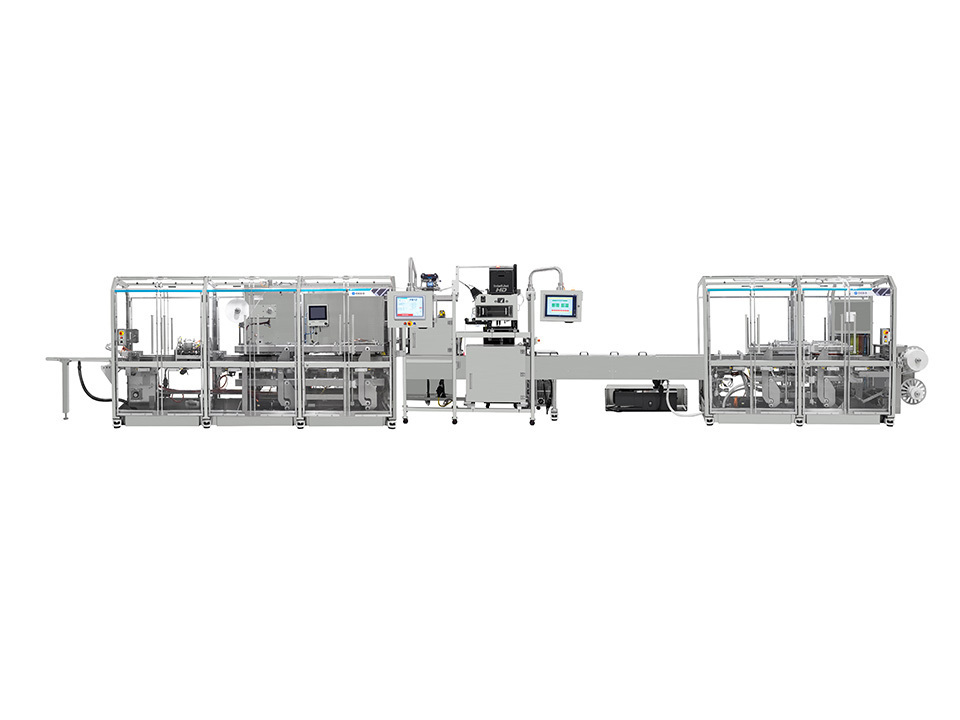

Ossid's line of horizontal form fill seal packaging solutions include Reepack thermoformers and our highly customizable Medical Device machines. All of these machines offer customers unique features ranging from the ability to handle a wide variety of materials to high speed output to meet your packaging requirements.

Our horizontal form fill seal machines can run flexible, semi-rigid as well as rigid films. They can produce ambient, modified atmosphere (MAP), vacuum pack, as well as vacuum skin pack (VSP) packaging formats.

The Reepack Series of thermoformers offer customers entry-level, low volume machines up to more complex and higher production machines. These stainless steel machines are made to withstand wash down environments and the easy open frame allows for quick access to check, adjust, or repair parts with ease. Machine options include pre-heat stations, easy forming and sealing tooling change, filling and printer integration, and many other features. Ossid, the North American master distributor of the Reepack brand provides all sales and support including parts, service, and training.

Ossid's line of Medical Device horizontal form fill seal machines are manufactured in the USA with several machine options to suite your product needs. Choose from the 800, 8000 or 8000S depending on what your packaging requirements are. These machines have the capability to form and seal a wide variety of flexible and rigid medical films including Tyvek. Machines can be built for cleanroom environments and include vision and leak detection systems to further protect the product. The 8000 is designed and built in accordance to the AMI sanitary principles with speeds up to 30 cycles per minute. No matter your needs, our engineers can design the machine for you!

Designed with reliability, all of our form fill seal packaging equipment provides efficiency in production rates and precision in each application.

The ReeForm Series is a thermoforming packaging machine offering a wide range of machines to meet customer individual requirements.

Ossid's 8000 Series of thermoform fill and seal machines can fit your specialized medical packaging needs.